Manufacturing

Test Content

Triple Shot Mold

6 facilities. 37 presses. This is where our expertise takes form.

From molding to assembly and finishing, we assist our customers from original idea to finished solution. We also manufacture our own product lines. This is all done in a lean manufacturing environment, where waste is reduced and efficiency is maximized. At Cascade Engineering, we have the ability to provide a wide variety of molding processes, using the latest methods, for virtually any application.

It’s our core competency and the platform on which our manufacturing is based. Our injection molding capabilities span a full range of materials, from engineered plastics to recycled polymers. We host one of North America’s largest molding machines at 9,000 tons. With 97 molding machines ranging from 50T to 9,000T, we can mold small and large parts, allowing for complex geometries, high-quality finishing, and structural integrity.

By injecting two or three materials into a mold simultaneously in specific areas, we’re able to create unique designs and functional features. Combining materials this way also creates design aesthetics, increased functionality, durability, and quality.

Injecting gas during the molding process pushes resin to the outer edge of the cavity, providing uniformity while offsetting the effects of resin shrinkage. This creates greater consistency, minimizes warp, reduces the part’s weight, and increases design freedom.

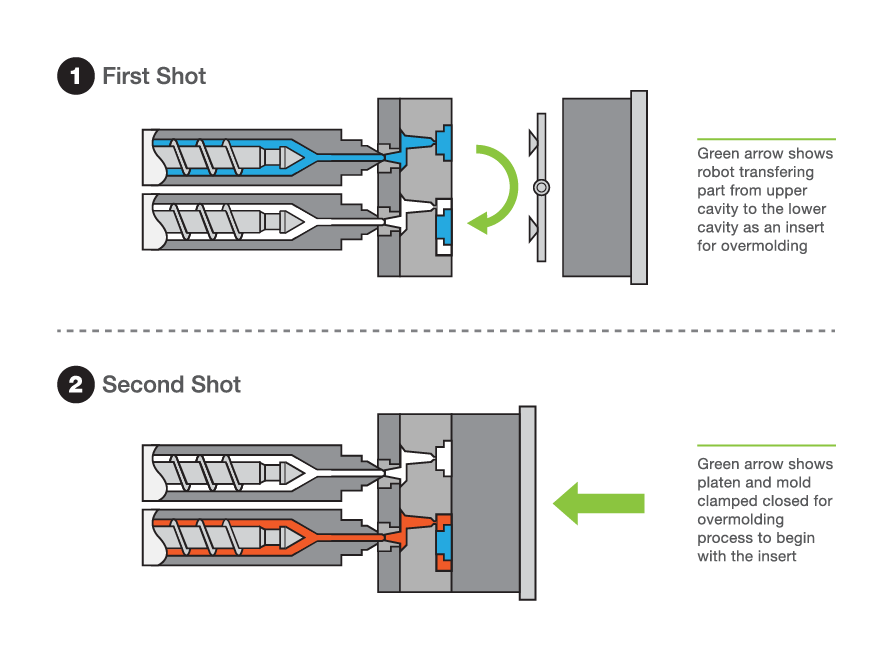

Multiple parts become a single component with the injection of thermoplastic. By creating one strongly bonded part, we can reduce assembly and labor costs, enhance design flexibility, minimize size and weight, and increase the part’s physical strength.

For graphics that stand out and stand up, there’s in-mold labeling. A label is placed in the mold, hot plastic permeates the label, and language/graphics become permanently integrated with the object. Years ago, we pioneered the method of in-mold barcode labels in carts, enabling better asset tracking and management in the real world.

Utilizing hot stamping, we’re able to provide information or brand identification once a product is molded. In applications like waste and recycling containers, hot stamping enables customers to display company or city logos, serial numbers, and unique program instructions.

No matter the product or manufacturing method, material matters. From recycled HDPE to our own specialty compounds, our expertise allows us to match the ideal material(s) with the design vision and end use in mind.

For specialty applications, we develop and manufacture high-performance thermoplastic materials in-house. Whether for industrial uses or consumer goods, we rise to the challenge of formulating completely customized compounds.

Assembly cells equipped with robotics, camera control units, and poke yoke systems allow the production of millions of units per year. We manufacture on a semi-automated or fully automated basis and have labeling capabilities that ensure total traceability for every assembled part.